Leaders in Dewatering Solutions

Advance solutions for tailings management, concentrates dewatering & waste treatment.

Our solutions

-

Tailings

-

Metal Concentrates

-

Coal

-

Lithium

Advanced Tailings Management

We integrate 3 processes in one, combining, desliming, settling & filtration technology, to offer a cutting-edge tailings management solution. Reduces energy consumption and operating costs, ensuring efficient tailings treatment.

Benefits

- 3 processes in one

- Improved Filtrate Quality

- Up to 250 t/h per Filter Press

- Reduction in Operating Costs

- Lower Energy Consumption

Equipment

- Advanced Processing Solution

- HCM / HCH Hydrocylone

- THDS Dewatering Screen

- APN / APNH Filter Press

- SIX Slurry Pump

- NK Paste Thickener

- NK-CL Thickener

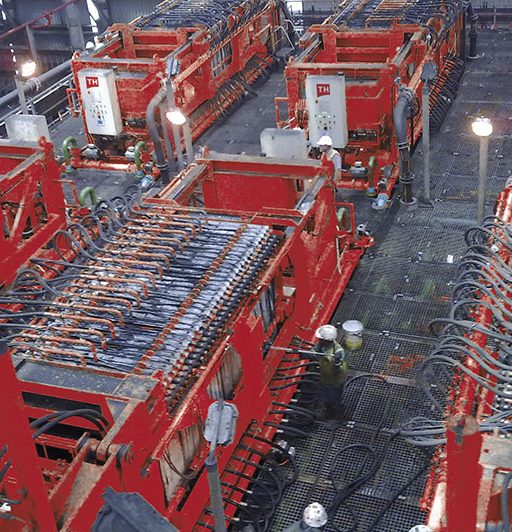

Metal Concentrates Dewatering

Complete solution for polymetallic concentrates (copper, zinc, lead), iron ore, or rare earths dewatering. High production capacity, lower energy consumption, and operational simplicity.

Benefits

- High production levels.

- Lower energy consumption.

- Exclusive design that facilitates operation and maintenance.

- Extended equipment life cycle.

Equipment

- APNQ / APNP / APN / APNH Filter Press

- SIX Slurry Pump

- NK Paste Thickener

- Auxiliary Components

Coal Concentrate & Tailings Dewatering

We assist our clients with coal concentrate pulps dewatering complete solutions, of as well as with advance coal tailings management technology.

Benefits

- High production levels

- Lower energy consumption.

- Maximizes the recovery of value-added product.

- Exclusive design that facilitates operation and maintenance.

Equipment

- APNQ / APNP / APN / APNH Filter Press

- SIX Slurry Pump

- NK Paste Thickener

- Auxiliary Components

Filtration Solutions for the Lithium Industry

Filtration solutions for lithium refineries and lithium carbonate processing plants, either through lithium brines or spodumene. We are one of the few companies in the market with proven experience in lithium mining and refining processes.

Benefits

- High production levels even in the most adverse conditions.

- Lower energy consumption.

- Maximizes the recovery of value-added product.

- Exclusive design that facilitates operation and maintenance.

Equipment

- APN / APNH Filter Press

- SIX Slurry Pump

Success Stories